Our recently completed project at Town Square in the MetroCentre is the first phase of an ambitious asset enhancement masterplan to reposition and diversify the centre.

The project’s success has proved to be both experiential and commercial, helping to secure a number of exciting leases in adjacent redundant units including H-Beauty, Harrod’s beauty trading brand with other innovative non-retail offers in negotiation.

The ambition behind the design was to reactivate a tired space with a fresh new interior, reintroducing greening and soft finishes to promote a theme that “brings the outside in”. As part of this vision, a central visual feature was proposed in the flooring which introduces a new banding of tiles to suggest the form of a “flowing river” across the space. The design went further to define this gesture by proposing a series of “pebble seats” which could be deployed in clusters around the edges of the tile feature to reinforce the natural metaphors. These pebbles would offer a new type of perch-seating in the space which could be more playful and intended to compliment the extensive sculpted timber benches around the edges of the space which offer more traditional comfort-seating.

The pebble seats were originally specified in the concept design as an off-the-shelf recast stone product but through technical design and testing, the weight of the seats became an issue. At over 300 kg per unit, each of these seats was too heavy to be easily moved around, making both installation an issue as well as limiting future flexibility should Town Square need to be cleared for use as an event or exhibition space. The weight also appeared to cause cracking and damage to the existing tiles and underlying screed which were to be retained as part of a budget-saving exercise but remain poorly founded due to their original 1980s specification. The client was heavily invested in the pebbles and saw them as a really strong gesture in the overall aesthetic of the space and so the challenge given to Leslie Jones and the design team was to deliver the same durable cast stone pebbles but in a lighter weight, less inhibiting construct.

As no suitable product could be found on the market, the team decided to approach Raskl (www.raskl.co.uk), a Newcastle based multi-disciplinary art and sculpture designer and fabricator, who specialise in collaborative working with artists and Architects. The Leslie Jones team have worked with Raskl before on the Newcastle City Centre Transformation Project alongside LDA Design for Newcastle City Council.

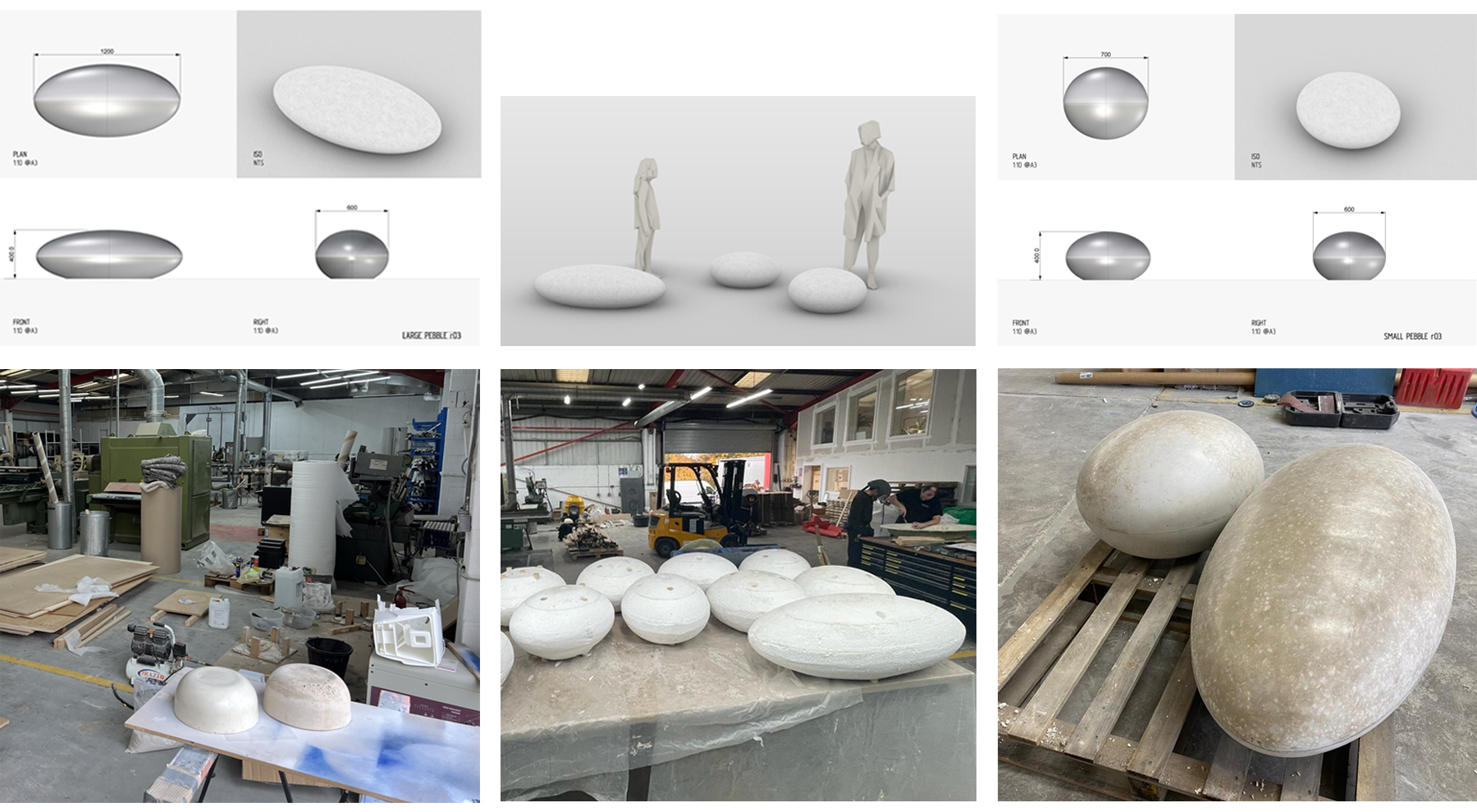

Together, the teams developed and tested a series of forms, materials and moulding processes to optimise casting finishes and develop a technique to create the lightweight pebble seating. Using 3d digital design tools, the designers created two optimum pebble shapes: a large 1200mm diameter and small 600mm diameter flattened eclipse. It was important to the design that the curved form sat up from the floor forming an undercroft, as a pebble would lay against the ground, not just a curved shape which sat dumped flat against the floor. This alone created issues for the designers as it dictated a process which required two moulds, one for each side of the curve, allowing the half-eclipses to be joined and form a continuous curved shape.

The stone mix was also extensively tested with numerous bucket-moulds of various tones and grades of aggregates used- once cured, these were taken to site and a favoured colour, texture and finish selected by the design team.

After numerous experiments, the team found a technique that set the cast stone around a non-compressible foam centre. These lightweight cores were carved using hot-wire to timber laser-cut wooden templates and the foam sat neatly inside the outer fibreglass moulds during the casting process, allowing for the concrete mix to be poured around them. This hugely reduced the amount of stone aggregate required in each pour without compromising the structural integrity. The two sides of the moulds were then bonded together, allowed to set before the outer casings were removed. A post-production exercises then rubbed back the mould joint, cleaned off any excess and treated the exposed stone with a wax-finish which gave the surface a degree of grip to assist users of the seats as well as provide protection from scratches, spills and wearing. A thin black-stained plywood base was also fixed to the bottom of each pebble with felt material boned to the underside to ensure a tidy edge and assist with cleaning floors under the seats.

The 6no large and 12no small pebble seats were cast in batches and delivered to the MetroCentre on palettes, carried into the space and set down in marked positions by man-handled pallet trucks. The stones are laid in clusters, focused around the base of columns- this has been found to help the stones be visible and reduces the potential trip hazard of low-level objects. At circa 55-65kg each, even the largest pebble can be moved by a team of two but each has enough weight that they are stable and can’t be moved easily by the public.

The team are now investigating further rollout of the pebble seats at MetroCentre and potentially at other projects now that the moulds are formed and a manufacturing technique tested. Please contact the Leslie Jones team should you want to understand more about the product and process.